Why you need a Fertilizer Injector for Your Garden!

This high-quality fertilizer injector is designed to deliver precise nutrient injection, regardless of flow or pressure conditions.

With a proportional range of 1% to 10%, it offers precise nutrient fertigation control in a wide range of applications, including hydroponic dosing, livestock feeding, and general farming needs, all without requiring external power sources.

Crafted from UV and corrosion-resistant materials, this kit includes replacement seals, ensuring reliable operation for years, even in diverse environmental conditions. Say goodbye to ineffective venturi devices; we’ve tested numerous options and can confidently say that these are the top performers available in the market.

The introduction of fertigation technology has significantly enhanced modern agricultural production. With the right fertigation equipment, fertilizers can be seamlessly incorporated into irrigation water, allowing the fertilizer to travel with the water throughout the system.

Fertigation ensures that fertilizer is applied precisely where and when it is required, in the ideal dosage and quantity.

What is a Fertilizer Injector?

For decades, these devices have been integral to large-scale agriculture and farming operations. They operate solely on water pressure, harnessing its force to function effectively. As water enters through the inlet, it initiates an internal suction mechanism akin to a toilet plunger. This action generates a vacuum within the device, pulling nutrients from a reservoir below and injecting them into the water stream at precise rates, ranging from 0.4% to 4% of the total flow.

Advantages

- No electricity needed

- No pumps needed (if using water mains)

- No reservoirs needed

- Injects fresh nutrient every feed

- No recirculation needed

- Long lasting, commercial quality

- Allows precise nutrient measurement

- Automated & easy to maintain

When is it best used? Why not just use a reservoir and pump?

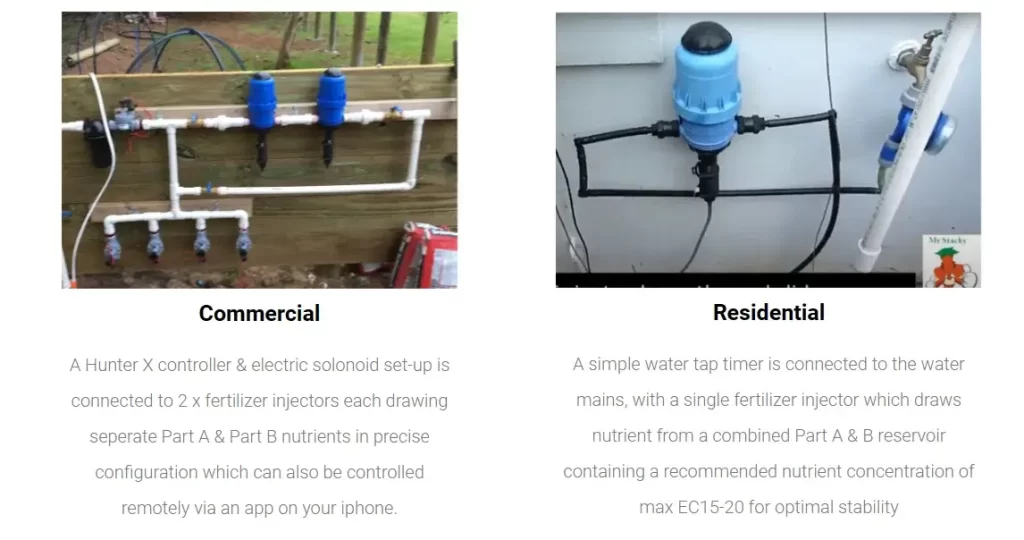

This configuration is most suitable for larger-scale operations that handle over 100 liters of water weekly. It translates to reduced reservoir management time. Since these systems depend on water pressure, they offer greater scalability compared to traditional water pumps. Just two injectors, one for Part A and one for Part B nutrients, are ample to efficiently supply an entire 100-tower farm.

Is it difficult to use?

Many customers are concerned about the complication of these devices and although they may seem difficult to understand, they are actually very simple. Just install it against a wall between the garden and your water mains or water tank. The hardest bit is ensuring the right EC to your garden. We show you exactly how to do this.

Watch our video:

How to mix Superior Blend Hydroponic Nutrient for Mr Stacky Fertilizer Injector Method

How to mix Superior Blend Hydroponic Nutrient for Mr Stacky Fertilizer Injector Method – YouTube

General Questions

How long do they last?

These devices include a one-year warranty covering malfunctions and parts replacement. Additionally, they are equipped with replacement seals that can be employed after the first year, allowing you to extend the device’s lifespan significantly, well beyond 2 to 5 years.

How similar is it to a Venturi?

In essence, this represents a premium-grade venturi system. While you can find smaller venturi devices for as low as $20, our experience has shown that they often prove ineffective. They lack precise suction control, leading to wasteful nutrient usage. Moreover, the venturis we’ve examined tend to be temperamental; they might function adequately for a day and then encounter suction issues, leaving you constantly uncertain about their performance. These injectors, on the other hand, are specifically designed for commercial growers who demand consistent and durable solutions. While they come at a higher cost, the reliability and longevity they offer make them a valuable investment.

What problems are most common?

Usually, the primary concern arises from the accumulation of mineral salt deposits within the 6mm hose that extends into your nutrient solution. You can easily address this by performing a biweekly cleaning using a wire or by flushing it with clean water.

How does the Part A and B Nutrient work with it?

For commercial farms, we recommend 2 x injectors. 1 for Part A & 1 for Part B. However for smaller residential set-ups, simply use 1 injector and combing the Part A & B nutrient in one reservoir at an EC of 15. This ensures no significant nutrient ‘lock-out’ or detrimental results. See these results. (All based on 1 injector and combined Part A &B at EC15)

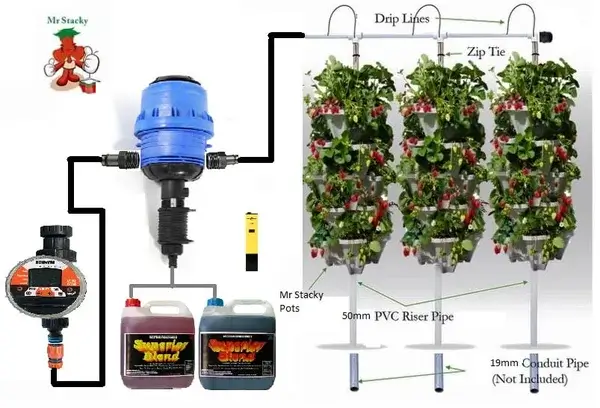

Injector Configurations

Operating without any reliance on external power sources, this fertilizer injector delivers precise injection of liquid fertilizer containing dissolved nutrients. Its automated dosing system is meticulously designed to maintain accuracy across diverse environmental conditions.

Irrespective of the input flow rate or pressure, the output solution’s dosage remains consistently proportional and adjustable within the 1% to 10% solution range based on the configuration.

Cultivate Larger, Faster and Superior Results

See how the pump works in video form below.

About the Author

Mr Stacky is the leader in Tower Garden Systems in Australia, specializing in commercial hydroponic farming, urban farming & residential vertical gardening.

Find out how he can help you achieve your food production goals. Contact Brian